The Sweet Science of Keeping it Cool (and DELICIOUS)

Summary

Baking with allulose delivers incredible flavor, color, and clean sweetness—but its high Maillard reactivity means it browns fast, behaves unpredictably under heat, and requires a different approach than sucrose. In this technical breakdown, we explore why allulose caramelizes so quickly, how to adjust bake temps and dwell times for ideal results, and why pairing allulose with Glycera™ vegetable glycerin is the key to managing moisture, preventing scorching, and creating soft, beautifully textured baked goods. From thermal thresholds to hydrogen bonding, this guide gives formulators the science and tools needed to master allulose and unlock consistent, consumer-ready performance.

Authored by:

Thom King, Icon Foods

Chief Innovations Officer/Certified Food Scientist

Allulose has strutted into the baked-goods world like the rockstar of rare sugars, and for good reason. It brings about 70% of the sweetness of sucrose, browns like a dream, and somehow manages to dodge the caloric baggage that sugar drags around. But before you crank up the oven and let your cookies tan too hard, let’s talk about the fine art — and science — of baking with this tricky but wonderful molecule.

The Burn Notice: Why Allulose Gets Toasty Fast

Here’s the thing: allulose is a reducing sugar, and that means it loves to join the Maillard party. In simple terms, it’s hyper-reactive with amino acids and proteins under heat, which translates to beautiful golden color, unless you push it too far, and your golden turns to “help, I scorched the muffins again.”

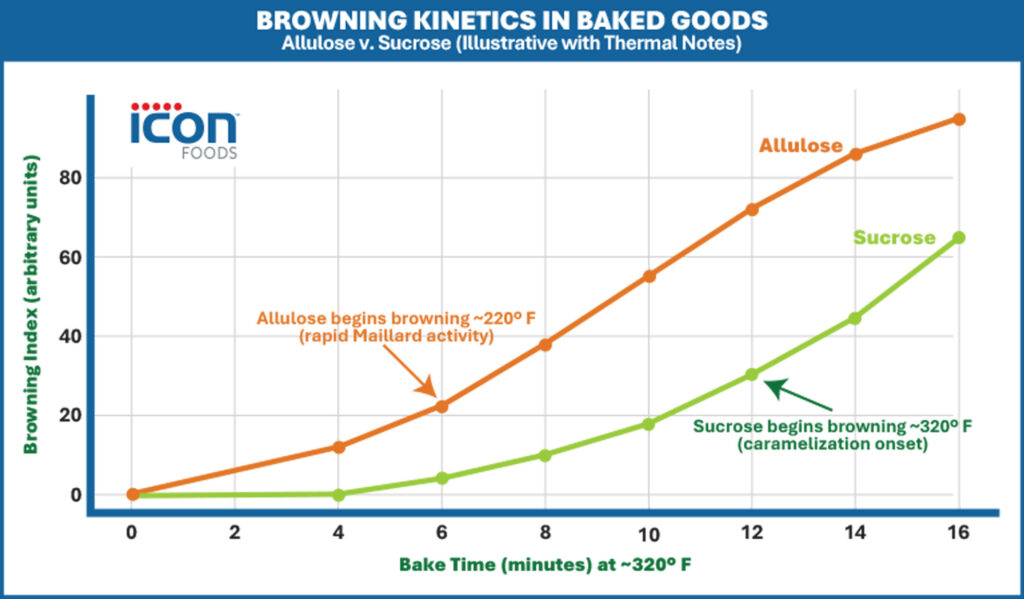

Unlike sucrose, which must hydrolyze before browning, allulose is already primed for the Maillard reaction. It’s like the over-eager kid in chemistry class, who is ready to react before the teacher finishes the instructions. That’s why allulose will brown at around 220–230°F, while sucrose won’t show much color until around 320°F. So yes, lower your oven temps. A good rule of thumb? Drop your bake temperature by 25–35°F and extend your bake time a touch to even out the heat distribution.

Above is a chart highlighting Maillard reactivity and thermal thresholds for both sweeteners — showing that allulose starts browning around 220°F while sucrose doesn’t caramelize until ~320°F.

Cool It Down: The Temperature Sweet Spot

Allulose doesn’t like high heat, but it loves gentle warmth. Think “spa day,” not “furnace.” When formulating, target a baking temperature between 300°F and 325°F and allow for a slightly longer dwell time. This gives your dough or batter the chance to fully set and retain structure before surface burning happens. The result? Perfectly caramelized flavor, beautiful color, and zero bitterness.

Meet Glycera™: The Humectant Whisperer

Now, let’s introduce your new best friend in allulose formulation: Glycera™ vegetable glycerin, our clean-label, plant-based humectant designed to tame the wild side of allulose.

Glycera™ steps in where traditional vegetable glycerin left off, keeping your baked goods soft, chewy, and moist without the stickiness or off-notes of conventional humectants. It’s your all-in-one texture stabilizer, moisture manager, and browning bodyguard.

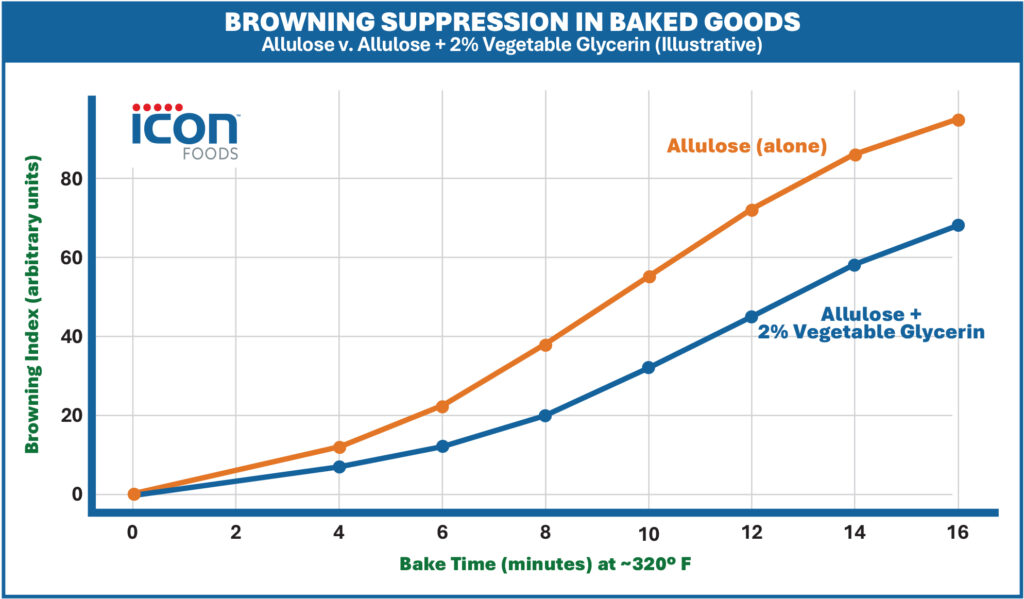

At 1–3% inclusion, Glycera™ helps manage both texture and moisture migration. It moderates the rate of water loss, reduces surface scorching, and creates that soft bite, “fresh from the oven” feel long after cooling.

Pair Glycera™ with allulose and you’ll discover what we call sweet alchemy: indulgent mouthfeel, balanced color, and clean sweetness that lasts.

Above is an illustrative chart comparing browning for allulose alone vs allulose + 2% vegetable glycerin across bake time (held around ~320°F).

The Science Behind the Magic

So how does Glycera™ pull this off? It’s all about hydrogen bonding and thermal moderation. Allulose has a low melting point and caramelizes quickly, which makes it prone to over-browning. Glycera™ acts as a molecular buffer, retaining free water and dispersing heat more evenly through the matrix. This keeps allulose from peaking too early in the Maillard reaction—and your cookies from looking like lava rocks.

It also enhances mouthfeel by mimicking the plasticizing properties of sucrose and lowering water activity (aᵥ). Lower aᵥ equals longer shelf life, better microbial stability, and that perfectly soft bite that consumers crave.

Pro Tips for Formulators Who Want to Bake Smarter

- Start low, go slow: Drop your bake temp by ~30°F and bake a few minutes longer.

- Add 1–3% Glycera™: It’s your anti-burn ally and moisture bodyguard.

- Blend your sweeteners: Allulose + erythritol or monk fruit = balance in sweetness, color, and structure.

- Hydration check: Keep doughs and batters 1–2% wetter than sucrose versions.

- Color watch: Aim for golden, not mahogany—when allulose goes dark, it gets bitter.

The Final Bite

Baking with allulose is a dance between heat, time, and chemistry. It’s not a plug-and-play sugar replacement—it’s a craft. But when you pair allulose with Glycera™ vegetable glycerin, the results speak for themselves: beautiful golden bakes, soft crumb structure, and that sweet, clean flavor that makes your brand stand out on the shelf.

So turn down the heat, invite Glycera™ vegetable glycerin to the party, and let allulose do what it does best—deliver sweetness, mouthfeel, and clean label brilliance in every bite.

Since 1999, Icon Foods has been your reliable supply-chain partner for sweeteners, fibers, sweetening systems, inclusions, and sweetness modulators.

Reach out to your Icon Foods representative for a beverage formulating toolkit with samples, documentation, and formulation guidance for: Glycera™ vegetable glycerin, FibRefine™ (Soluble Tapioca Fiber, PreBiotica™ Organic Agave Inulin, MonkSweet™ Monk Fruit, SteviaSweet™ RM95D, and KetoseSweet+® Allulose blends.

Taste the Icon difference.

Request samples!

x