Summary

Formulators today need more than a sweetener — they need agility. As stevia markets shift and purity grades fluctuate, the ability to convert seamlessly between Rebaudioside A levels (RA60 through RA99M) has become a powerful competitive advantage. This white paper breaks down the simple yet essential conversion math that keeps sweetness intensity consistent across grades, explains how steviol equivalency maintains flavor fidelity, and outlines best practices for dissolvability, foam control, and processing efficiency. The result is a practical framework for ensuring supply-chain resilience, cost optimization, and formulation consistency — all while delivering cleaner taste and better performance. When you understand the science behind Reb A conversion, you unlock true formulation flexibility and future-proof your brand.

Authored by:

Thom King, Icon Foods

Chief Innovations Officer/Certified Food Scientist

In formulation and in life it pays to stay flexible. Ingredient markets shift, freight rates fluctuate, and purity grades vary. When you’re working with stevia extracts, particularly Rebaudioside A (Reb A), being able to pivot between different grades without compromising sweetness, texture, or label compliance is a hallmark of a seasoned formulator.

Having the ability to move from RA60 to RA97 or RA99M isn’t just about convenience it’s about resilience. It’s the art of designing flexibility into your formula so you’re never at the mercy of a single supplier, purity spec, or price spike.

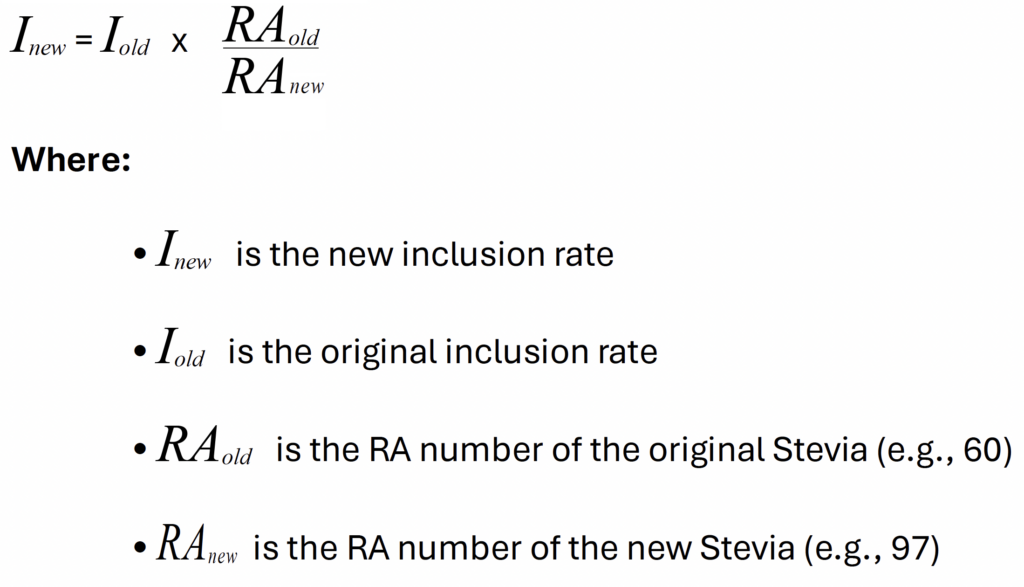

The Conversion Formula: Your Stevia Compass

When converting between stevia grades, the goal is to maintain equivalent sweetness intensity while accounting for the change in glycoside purity. The formula is refreshingly simple but incredibly powerful:

Example

If your formula uses 2% Stevia RA60 and you want to convert to RA97:

(60 ÷ 97 = 0.619).

Multiply that by your inclusion rate: (0.619 × 2 = 1.238%).

Your new inclusion rate is 1.238% RA97, giving you the same sweetness performance and flavor balance as the original.

Quick Reference Conversion Table

| From → To | RA60 | RA80 | RA95 | RA97 | RA99M |

|---|---|---|---|---|---|

| RA60 | 1.000 | 0.750 | 0.632 | 0.619 | 0.606 |

| RA80 | 1.333 | 1.000 | 0.842 | 0.825 | 0.808 |

| RA95 | 1.582 | 1.188 | 1.000 | 0.979 | 0.961 |

| RA97 | 1.616 | 1.212 | 1.021 | 1.000 | 0.981 |

| RA99M | 1.650 | 1.238 | 1.041 | 1.019 | 1.000 |

Pro tip: When converting to higher-purity Reb A (95+), consider rounding down slightly. The cleaner sweetness and reduced bitterness often mean you can use a bit less while maintaining your sensory balance.

Understandint Steviol Equivalency – NERD ALERT

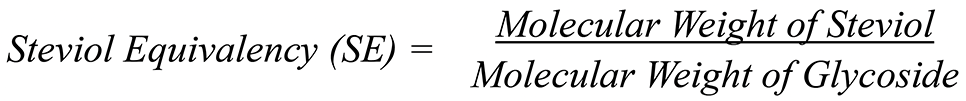

Reb A isn’t sweetness in isolation—it’s part of a family of steviol glycosides, each contributing to the overall steviol equivalency (SE). SE represents the relative sweetness potency of a stevia extract compared to a reference sucrose solution, standardized by its steviol backbone content.

For example:

- Pure Reb A 97% has ~250–300× the sweetness of sucrose.

- Reb A 60% lands closer to ~200×.

- The remaining 40% of the extract (non-Reb A glycosides, fiber, or carrier solids) dilutes the overall steviol potency.

When you adjust formulas, you’re not just balancing purity—you’re balancing effective steviol units. The conversion formula above already accounts for this by aligning the glycoside percentage, but formulators who want absolute precision can use SE values as a second check:

By maintaining equivalent SE values across stevia grades, your product’s sweetness profile stays true, even if the paperwork, vendor, or crop conditions change.

Why Being Flexible Pays Off

Building flexibility into your formulation strategy delivers three big wins:

- Supply Chain Resilience – If one purity grade goes tight, you can swap grades and keep your production schedule intact without rewriting your ingredient declaration or nutrition panel.

- Cost Optimization – Higher-purity Reb A (RA95 and above) commands a higher price per kilo but delivers more sweetness potency and cleaner taste, which translates into lower inclusion rates and long-term savings.

- Consistency and Control – Variations in purity between suppliers can alter sweetness perception and functionality. Having your conversion math dialed in keeps your formulation consistent and your QC team happy.

The Science Behind Dissolvability

Here’s where things get practical. The higher the purity, the more crystalline and less soluble the stevia extract becomes. Reb A 95, 97, and 99M can be stubborn in cold or acidic systems, leading to hazing or sedimentation if handled carelessly.

Managing Foaming and Aeration

Reb A molecules can lower surface tension during mixing, especially under high shear. This can introduce foaming an annoyance in beverages, frostings, and aerated systems where volume and clarity matter.

To Keep Foam at Bay

- Add stevia early in the batching process so trapped air can release before final homogenization.

- Use a gentle impeller speed during introduction to minimize turbulence.

- If necessary, employ a light vacuum sweep or food-grade defoamer (simethicone works beautifully) to tame the froth.

Small adjustments in your processing sequence can mean the difference between a clean pour and a bubble bath.

The Takeaway

Formulation flexibility isn’t just a technical advantage it’s a business strategy. The ability to move gracefully between Reb A grades without compromising taste or performance keeps your supply chain nimble and your products consistent.

So, stay flexible my friends. Know your math. Hydrate your stevia, control your shear, and keep your foaming in check. Because in a world of volatile markets and evolving consumer demands, the most successful formulators aren’t just scientists they’re adaptive problem-solvers who can pivot fast and finish strong.

That’s how you future-proof your formulations and your brand.

Since 1999, Icon Foods has been your reliable supply-chain partner for sweeteners, fibers, sweetening systems, inclusions, and sweetness modulators.

Reach out to your Icon Foods representative for a pricing and inventory visibility for stevia today.

Taste the Icon difference.

Order Samples!

x