The Gummy Evolution

Summary

Gummies have evolved from candy-aisle treats into functional delivery systems for vitamins, botanicals, and wellness actives, but consumers now expect indulgent texture and sweetness without added sugar. This white paper explores how formulators can successfully rebuild the gummy matrix by replacing traditional sucrose and glucose syrup systems with soluble fibers, rare sugars, and precision sweetener stacks. By leveraging FibRefine™ soluble fibers, KetoseSweet® allulose, and balanced high-intensity sweeteners, brands can deliver the chew, bounce, and temporal sweetness consumers love while achieving no-added-sugar, prebiotic fiber, keto-friendly, and clean-label claims. The result is a new generation of gummies that taste like candy, perform like functional nutrition, and meet modern regulatory and consumer expectations.

Thom King, CFS, Food Scientist

Chief Innovations Officer, Icon Foods

Let’s face it, gummies have gone from a kid’s candy aisle indulgence to a functional delivery system for everything from vitamins to collagen to adaptogens. Consumers want the chew, the bounce, and the nostalgic hit of sweetness, but they don’t want the baggage of added sugars. The challenge for formulators? Delivering that same indulgent sensory profile, chewiness, sweetness, clean release, without sucrose, corn syrup, or glucose syrup doing the heavy lifting.

Luckily, we’ve now got the fiber systems, rare sugars, and sweetener stacks to pull it off.

Building the Foundation: Replacing the Syrup System

Traditional gummies rely on glucose syrup for structure and sugar for sweetness. Take those out, and you’re left with two challenges:

- Bulk and binding – how to build that chew.

- Temporal sweetness – how to mimic sugar’s onset, peak, and finish.

This is where soluble dietary fibers like FibRefine™ P90 (soluble tapioca fiber), FibRefine™ GA (gum acacia), and FibRefine™ HG (partially hydrolyzed guar gum) shine. These fibers not only bring viscosity and film-forming qualities, but also add prebiotic functionality. Soluble tapioca fiber in particular gives a mild gelling effect that works synergistically with gelatin or pectin to deliver that familiar bounce.

By Stacking Fibers, You Get:

- Structure and chew (P90)

- Film-forming stability (GA)

- Water-binding and gut health halo (HG)

Sweetness Without Sugar

Sugar’s curve is a tough act to follow, but with the right stack, you can get shockingly close. My go-to for gummies:

- Allulose (2–4%): bulk sweetener, reduces water activity, browning potential for flavor depth.

- SteviaSweet™ RA99M or RM95D (30–60 ppm): clean high-intensity lift with no bitterness.

- MonkSweet™ V40 or V50 (20–40 ppm): rounds out sweetness with a fruit-like finish.

- ThauSweet™ VRM (20 ppm): thaumatin + monk fruit for temporal balance and sugar-like linger.

This combination emulates the upfront hit, mid-palate roundness, and lingering finish of sucrose, without the crash or calories.

Gelling and Stability: Heat, pH, and Texture

For formulators, stability is non-negotiable. Gummies face heat during cooking and pH challenges when paired with fruit acids or actives. Here’s what works:

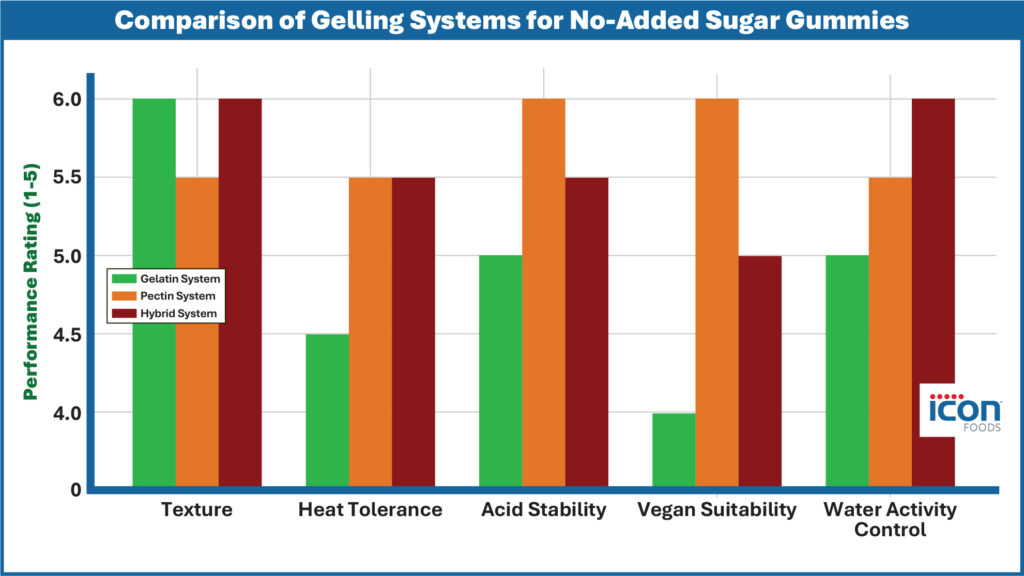

- Gelatin systems: Classic chew, but can be sensitive to high heat. Works best with allulose + fiber syrups cooked below 120 °C (248 °F).

- Pectin systems: Acid-stable, vegan-friendly, and compatible with high-fiber syrups. Use amidated pectin for flexible textures.

- Hybrid systems: Pairing soluble tapioca fiber with gelatin or pectin for improved bite and water activity control.

Above is a chart illustrating the performance comparison of gelatin, pectin, and hybrid gelling systems for no-added-sugar gummies.

pH sweet spot is 3.2–3.8 for fruit-forward gummies, low enough to pop flavor, high enough to preserve structure.

Below is a data-driven comparison chart that contrasts a traditional sugar-based gummy with the Icon Foods no-added-sugar gummy system

Gummy Formulation Comparison: Traditional vs. Icon Foods No-Added-Sugar System

| Attribute | Traditional Gummy (Sugar & Glucose Syrup) | Icon Foods No-Added-Sugar Gummy (FibRefine™ + KetoseSweet® System) |

|---|---|---|

| Total Sugars (per 40 g serving) | 26–32 g | 0 g added sugar (< 2 g total) |

| Fiber Content | 0–1 g | 6–8 g soluble fiber (prebiotic) |

| Net Carbohydrates | 32–36 g | 2–4 g |

| Sweetener System | Sucrose + glucose syrup | KetoseSweet® Allulose + FibRefine™ fiber + SteviaSweet™ + MonkSweet™ + ThauSweet™ |

| Gelling System | Gelatin or pectin (high solids, sugar-dependent) | Gelatin or pectin + fiber syrup matrix |

| Calories (per 40 g) | 140–160 kcal | 60–70 kcal |

| Glycemic Response | High (rapid glucose spike) | Low / negligible (allulose + fiber matrix) |

| Shelf Stability | Moderate – depends on humectants and water activity control | Excellent – low water activity (0.55–0.65) and fiber stability |

| Label Claims | “Contains Sugar” / “High in Carbs” | “No Added Sugar” / “Keto-Friendly” / “Prebiotic Fiber” / “Clean Label” |

| Consumer Appeal | Indulgent but guilt-laden | Indulgent and functional, health-halo meets nostalgia |

| Regulatory Alignment | Must declare added sugars per FDA 21 CFR 101.9(c)(6)(iii) | Qualifies for “No Added Sugar” claim per FDA 21 CFR 101.60(c)(2) |

| Ideal Use Case | Conventional candy and legacy brands | Functional snacks, nutraceuticals, better-for-you treats |

By replacing sucrose and glucose syrup with KetoseSweet® allulose and FibRefine™ fibers, you don’t just cut sugar, you add value: prebiotic function, keto compliance, and clean-label differentiation. This system gives formulators a gummy matrix that chews, stretches, and tastes like candy, but lands like a wellness product.

Sample Bench-Top Formulas

Gelatin-Based No-Added-Sugar Gummy (per 100 g batch)

- Water: 20.0 g

- Gelatin 250 Bloom: 7.0 g

- FibRefine™ P90 (soluble tapioca fiber): 30.0 g

- Allulose (KetoseSweet®): 25.0 g

- FibRefine™ GA (gum acacia): 5.0 g

- Citric acid solution (50%): 1.2 g (adjust to pH 3.4–3.6)

- SteviaSweet™ RA99M: 45 ppm

- MonkSweet™ V40: 30 ppm

- ThauSweet™ VRM: 20 ppm

- Natural flavor + color: q.s.

Process:

- Hydrate gelatin in water at 55 °C (131 °F).

- Heat FibRefine™ P90 + allulose to 110 °C (230 °F) until dissolved.

- Combine syrup with gelatin slurry, add gum acacia, cook to 118 °C (244 °F).

- Cool slightly (<90 °C / 194 °F), add sweetener stack, citric acid, flavors, and colors.

- Deposit into starch-free silicone molds. Dry at 40–45 % RH for 24 hours.

Finished specs: ~2.5 g fiber/serving, ~1 g net carb, water activity 0.58.

Pectin-Based Vegan No-Added-Sugar Gummy (per 100 g batch)

- Water: 24.0 g

- Pectin (amidated high-methoxyl): 3.0 g

- FibRefine™ P90 (soluble tapioca fiber): 35.0 g

- Allulose (KetoseSweet®): 20.0 g

- FibRefine™ HG (partially hydrolyzed guar gum): 4.0 g

- Citric acid solution (50%): 1.4 g (target pH 3.3–3.5)

- SteviaSweet™ RM95D: 50 ppm

- MonkSweet™ V50: 30 ppm

- ThauSweet™ VRM: 20 ppm

- Natural fruit concentrate (strawberry, orange, etc.): q.s.

- Color: q.s.

Process:

- Preblend pectin with allulose, then disperse in cold water.

- Heat mixture to 105 °C (221 °F) with agitation until pectin fully hydrated.

- Add FibRefine™ P90 and HG, cook to 112–115 °C (234–239 °F).

- Cool to 90 °C (194 °F), then add sweetener stack, acid, and fruit concentrate.

- Deposit into starch-free molds; cure 24–36 hours at 40–45 % RH.

Finished specs: ~3.0 g fiber/serving, vegan, acid-stable, water activity ~0.60.

Labeling & Consumer Appeal

The payoff for going sugar-free isn’t just technical, it’s marketing gold. Formulators can now lean into:

- “No Added Sugar” claim

- “Prebiotic fiber” callout with ≥3 g fiber/serving

- “Keto-friendly” positioning with <3 g net carbs

- “Plant-based” with pectin systems

Better-for-you gummies straddle the line between indulgence and function, giving consumers permission to snack and justify it.

Best Practices for Success

- Pilot scale first: Fiber and rare sugars behave differently in a beaker than in a 200-liter kettle. Dial in hydration curves and solids content before scaling.

- Control water activity: Aim for 0.55–0.65 for shelf stability without sugar’s humectant effect.

- Watch tolerance: Use allulose and fibers at levels that balance prebiotic benefit with gastrointestinal comfort.

- Flavor masking: High-intensity sweeteners can accentuate acids. Use flavor modulators or natural fruit concentrates to keep it clean.

Formulating no-added-sugar gummies isn’t about subtraction, it’s about re-engineering the matrix. By leveraging Icon Foods’ toolbox of fibers (FibRefine™ line), sweeteners (SteviaSweet™, MonkSweet™, ThauSweet™), and rare sugars (KetoseSweet® allulose), formulators can deliver gummies that are indulgent, functional, and clean-label compliant.

The future of gummies is clear: chewy, sweet, gut-friendly, and sugar-free. And the formulators who embrace this now will be leading, not following, when consumers demand their candy and their conscience in the same bite.

Since 1999, Icon Foods has been your reliable supply-chain partner for sweeteners, fibers, sweetening systems, inclusions, and sweetness modulators.

Reach out to your Icon Foods representative for a gummy formulating toolkit with samples, documentation, and formulation guidance for: FibRefine™ (Soluble Tapioca Fiber, FibRefine™ HG PHGG), PreBiotica™ Organic Agave Inulin, MonkSweet™ Monk Fruit, SteviaSweet™ RM95D, KetoseSweet+® Allulose blends, and ThauSweet™ VRM.

Taste the Icon difference.

Order Samples

x