… and Carmelization in Food Applications

Summary

Taming the Burn: Controlling Allulose’s Quick Browning and Caramelization in Food Applications explores one of allulose’s most misunderstood traits: its tendency to brown early and aggressively under heat. While allulose delivers clean sweetness, bulking, and low-glycemic benefits, its highly reactive nature makes it prone to rapid Maillard reactions and caramelization, especially in low-moisture, protein-rich, or high-pH systems. This white paper breaks down the science behind allulose’s fast browning behavior and explains why it reacts at significantly lower temperatures than sucrose. More importantly, it provides practical, formulator-ready strategies for managing color development without sacrificing functionality. From polyol blending and pH control to moisture management, protein selection, and thermal profile adjustments, the paper shows how to harness allulose’s strengths while dialing back its darker side. For developers working on baked goods, bars, RTDs, or clean-label confections, this guide offers a clear roadmap for achieving the right balance of sweetness, texture, and visual appeal, proving that allulose doesn’t need to be avoided, just managed intelligently.

Thom King, CFS, Food Scientist

Chief Innovations Officer, Icon Foods

If you’ve ever pulled a “clean label” cookie sheet out of the oven only to find that your perfect keto dough turned into a batch of bronzed sugar soldiers, you’ve met allulose’s darker side. Literally.

Allulose—our darling rare sugar—delivers 70% of sucrose’s sweetness, nearly zero calories, a low glycemic index, and that beautiful bulking and mouthfeel that makes reduced-sugar formulations sing. But left unchecked, it’s also a pyromaniac. It browns early and fast, thanks to its eager participation in Maillard reactions. That’s both its blessing and its curse. The trick is to channel that energy—not eliminate it.

The Science Behind the Burn

Allulose, being a reducing sugar, is primed for the Maillard reaction — an interaction between reducing sugars and amino acids that yield flavor, aroma, and color. While sucrose needs to hydrolyze before it gets reactive, allulose dives in headfirst. It starts to caramelize at roughly 100–110°C (212–230°F)—a good 30–40°C lower than sucrose, and rapidly darkens as it climbs past 150°C (300°F).

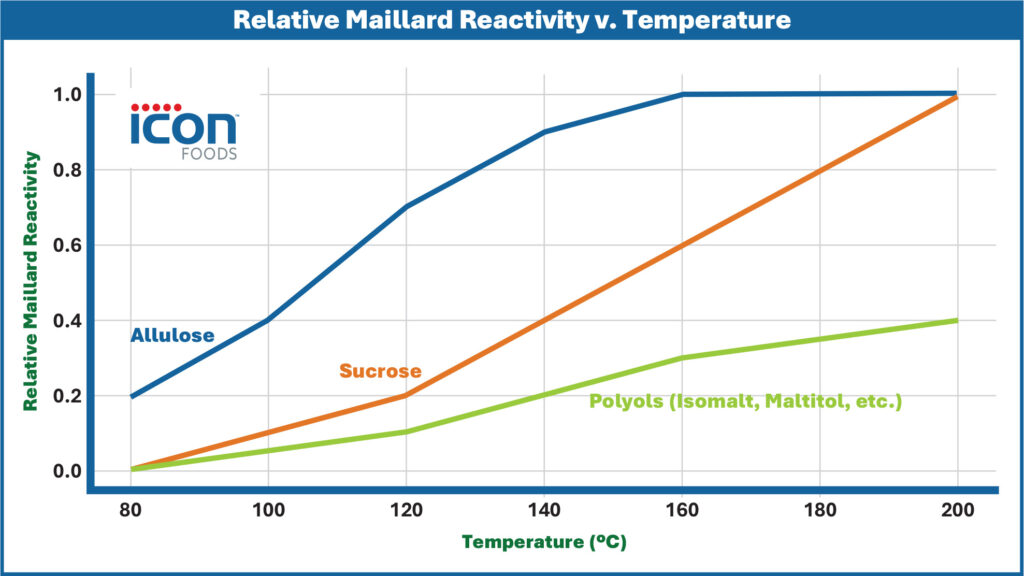

The chart (above) shows relative Maillard reactivity vs. temperature for sucrose, allulose, and polyols. It visually illustrates why allulose browns faster, its reactivity curve ignites earlier and climbs steeper—while polyols remain largely inert, acting as the perfect thermal stabilizers in balanced sweetener systems.

This high reactivity is amplified in:

- Low-moisture systems (like baked goods and bars)

- Protein-rich matrices (think dairy or nut inclusions)

- High-pH environments (where Maillard kinetics accelerate)

That’s why allulose performs beautifully in caramels and syrups, but can over-brown in cookies, cakes, or RTD applications during UHT processing.

Formulation Strategies to Rein It In

The goal isn’t to abandon allulose—it’s to balance it. A smart formulator uses its benefits (clean sweetness, freeze point depression, humectancy) while tempering its fast caramelization with polyols and other modalities.

Polyol Blending: The Brake Pedal for Maillard Madness

Polyols, being non-reducing sugars, act as excellent thermal and reactive buffers.

| Polyol | Role in Mitigating Browning | Recommended Use Level |

|---|---|---|

| Isomalt | Excellent thermal stability, high melting point (~145°C). Reduces overall Maillard reactivity and improves surface gloss. | 20–40% of total solids blend |

| Maltitol | Closest in mouthfeel to sucrose; buffers allulose’s reactivity while maintaining bulk and sweetness. | 20–50% |

| Erythritol | Non-reducing helps lower water activity and limit caramelization. May crystallize—use fine grind or co-blend with allulose. | 15–30% |

| Vegetable Glycerin | Acts as a humectant and thermal moderator. Ideal for baked goods, bars, and beverages. | 1–3% of formula weight |

When used in combination, these polyols effectively dilute the reactive carbonyl concentration and slow down the rate of Maillard color formation.

pH Control: Keep It Mild

The Maillard reaction thrives in slightly alkaline environments. Maintaining a pH between 5.5 and 6.5 keeps things under control. Acidulants like citric or malic acid can help stabilize pH in RTD beverages or fruit-based fillings.

Temperature & Time Adjustments

Allulose doesn’t need the same thermal energy as sucrose to brown. Try:

- Lower bake temperatures (by ~10–20°C)

- Longer bake times for even moisture removal

- Staggered heating (ramp slowly to final temperature)

In extrusion or UHT, this means dropping your peak temps by 5–8°C or shortening dwell times.

Water Activity & Moisture Management

Allulose’s hygroscopic nature makes water activity a key player. Maintaining an aw between 0.55–0.65 prevents excessive drying and subsequent over-caramelization. Polyols and fibers like or PreBiotica™ agave inulin, FibRefine™ soluble tapioca fiber can stabilize moisture migration and thermal stability.

Protein Source Matters

Milk proteins, whey, or soy all contribute free amino groups—fuel for the Maillard fire. Swapping to less reactive proteins (like collagen or certain plant isolates) can dial down the intensity. Enzyme treatment (e.g., protease hydrolysis) can also help neutralize free amines pre-blend.

The Fiber Synergy

Adding soluble fibers not only boosts label claims (“added fiber,” “reduced sugar”) but also slows thermal reactions by increasing viscosity and reducing surface heat exposure. FibRefine™ soluble tapioca fiber or PreBiotica™ soluble corn fiber pair beautifully with allulose for this reason.

Post-Processing Sweetness Boosts

If you’ve lowered your allulose load to avoid darkening, you can backfill sweetness with high-intensity sweeteners like SteviaSweet™ RM95 or MonkSweet™ LS4. These deliver the clean sweetness without contributing to Maillard coloration.

The Icon Foods Approach: Balanced Innovation

At Icon Foods, we’ve developed optimized sugar systems that leverage allulose’s functional magic without the browning baggage. Our hybrid sweetener systems (like KetoseSweet+™, MonkSweet™ LS4, and SteviaSweet™ blends) are designed to deliver that “just right” balance of sweetness, bulking, and thermal control.

Allulose is like those overly enthusiastic sous chef who caramelizes everything the second your back is turned. But with the right supporting cast—polyols, fibers, controlled pH, and smart process parameters—you can tame its enthusiasm and create products that deliver on taste, texture, and visual appeal.

Since 1999, Icon Foods has been your reliable supply-chain partner for sweeteners, fibers, sweetening systems, inclusions, and sweetness modulators.

Reach out to your Icon Foods representative for a fruit chew formulating toolkit with samples, documentation, and formulation guidance for: FibRefine™ (Soluble Tapioca Fiber, FibRefine™ HG PHGG), PreBiotica™ Organic Agave Inulin, MonkSweet™ Monk Fruit, SteviaSweet™ RM95D, KetoseSweet+® Allulose blends, and ThauSweet™ VRM.

Taste the Icon difference.

Order Samples

x